- Nuclear Update

- Posts

- ⚛️The Nuclear Fuel Cycle Explained: From Uranium Mining to Waste

⚛️The Nuclear Fuel Cycle Explained: From Uranium Mining to Waste

A step-by-step look at the nuclear fuel cycle

Welcome to a special holiday edition of Nuclear Update!

As the season glows with festive cheer and nuclear news hits a lull, we're turning the spotlight on the fuel that powers it all.

This week, we're diving deep into the nuclear fuel cycle. It's the full journey from raw ore to reliable energy, told with memes, metaphors, and mildly radioactive wordplay.

Also, a special thank you to reader "A", who inspired and greatly contributed to this week's newsletter.

Let's dive in!

⚛️The Nuclear Fuel Cycle Explained: From Uranium Mining to Waste

The Front End: From Ore to Fuel

Uranium Mining: Striking the Right Ore

The journey begins deep within the Earth, where uranium ore awaits discovery. Mining uranium is akin to prospecting for rare gems, requiring meticulous exploration and extraction techniques. There are three primary methods:

Open-Pit Mining: Ideal for deposits near the surface, this method involves stripping away overlying rock to access the uranium ore. It’s visually disruptive but cost-effective for large, shallow deposits, making it a "mine-tastic" choice when the ore is plentiful and accessible.

Underground Mining: For deeper ore deposits, underground mines are constructed. This approach minimizes surface disturbance but demands higher operational costs and stringent safety measures to protect miners from hazards like radon gas. Think of it as going deep-sea diving, but for uranium!

In-Situ Recovery (ISR): A more modern technique, ISR involves circulating oxygenated groundwater through porous ore bodies to dissolve uranium oxide. The uranium-laden solution is then pumped to the surface for extraction. ISR reduces environmental impact and operational intensity, making it an attractive option for certain geological settings. It’s like letting the uranium "float" to the top without the heavy lifting.

Uranium Milling: Crushing the Competition

Once mined, the uranium ore undergoes milling; a process that transforms raw ore into a concentrated form known as yellowcake (U₃O₈). Milling involves crushing and grinding the ore, then using chemical leaching to separate uranium from other minerals.

The result is a manageable, transportable substance that serves as the precursor to nuclear fuel. However, this stage also produces tailings, the residual waste material, which must be carefully managed to prevent environmental contamination.

These tailings are contained in specialized Tailings Management Facilities (TMFs), acting as the "guardians of the tail," ensuring that waste remains securely isolated and the environment stays pristine. It’s a balancing act, extracting the good while managing the not-so-great.

Conversion: Turning Yellowcake into Gas

Yellowcake is then converted into uranium hexafluoride (UF₆), a gaseous compound essential for the next phase: enrichment. Conversion facilities transform solid yellowcake into UF₆ gas. This step is critical because only in its gaseous form can uranium isotopes be effectively separated during enrichment. It’s the "gas" to fuel the enrichment engine.

Enrichment and Fabrication: Enhancing the Isotopes

Uranium Enrichment: Separating the Isotopes

Natural uranium consists primarily of U-238, with only about 0.7% being the fissile U-235 isotope needed for nuclear reactors. Enrichment increases the concentration of U-235 to between 3% and 5%, making it suitable for use as reactor fuel (typically around 5-7% for U.S. reactors, depending on the reactor design and operator preferences).

The primary method for enrichment is gas centrifuge technology, which exploits the slight mass difference between U-235 and U-238. UF₆ gas is fed into rapidly spinning centrifuges, where the lighter U-235 isotopes concentrate near the center and are separated from the heavier U-238. It’s a "spin-off" success story, literally spinning to separate the useful from the not-so-useful.

Note: It's important to recognize that nuclear processes are not standardized globally. For example, CANDU reactors in Canada use natural uranium and do not require enrichment, highlighting the diversity in nuclear reactor technologies around the world.

This is where the geopolitical tensions come into play. Russia, previously supplying about 25% of global enrichment, has curtailed exports following the Ukraine War. This turmoil has pushed Western nations to seek alternative enrichment sources. It’s a high-stakes game of energy chess, ensuring the nuclear fuel cycle remains robust against international uncertainties.

Fuel Fabrication: Crafting the Perfect Pellet

Enriched UF₆ is transported to fuel fabrication facilities, where it is converted back into solid form, uranium dioxide (UO₂) powder, which is then pressed into ceramic pellets. These pellets are sintered at high temperatures to enhance their structural integrity.

Once formed, the pellets are loaded into metal tubes to create fuel rods, which are bundled together into fuel assemblies tailored to specific reactor designs.

Fuel fabrication is a precision-driven process, where consistency and quality control are paramount. Any imperfections in the fuel rods can affect reactor performance and safety, underscoring the need for meticulous engineering and manufacturing standards. It’s the "pellet" you need to keep reactors running smoothly.

The Reactor: Harnessing Atomic Power

Electricity Generation: The Heart of the Cycle

With fuel assemblies in hand, the nuclear fuel cycle reaches its most visible stage: the reactor. Here, nuclear fission takes center stage. When U-235 atoms absorb neutrons, they split into smaller nuclei, releasing a tremendous amount of energy in the form of heat. This heat converts water into steam, which then drives turbines connected to electricity generators. It’s a cycle of transformation that mirrors the natural processes of our universe, scaled down to power our homes and industries.

But this process isn’t just about generating energy. It’s also about control and safety. Control rods, made of neutron-absorbing materials, regulate the reaction rate, ensuring it remains steady and manageable. The reactor core is a marvel of engineering, designed to contain the intense heat and radiation, much like a heart sustaining life within the body. It’s the "core" of the operation, literally and figuratively.

The Back End: Managing Spent Fuel

Spent Fuel Storage: Keeping it Cool

After years of operation, fuel assemblies become highly radioactive and must be carefully managed. Initially, spent fuel is stored in cooling pools at reactor sites, submerged in water to dissipate residual heat and act as a radiation barrier by absorbing harmful particles and radiation. This dual role of cooling and containment makes water essential for safely managing spent fuel.

However, this is a temporary solution, as the spent fuel continues to generate heat from radioactive decay and remains radioactive for tens of thousands of years. Think of it as a "cooling off" period for the spent fuel.

Note: Nuclear fuel cycle processes are not standardized globally. For instance, in the U.S., spent fuel is managed through long-term interim cask storage, whereas other countries may adopt different strategies for waste management and disposal.

Eventually, spent fuel is transferred to dry cask storage; robust, sealed containers made of steel and concrete. These casks provide long-term on-site storage solutions, isolating the radioactive material from the environment, and providing additional security against proliferation, especially considering the mass & size of the casks.

While dry cask storage is considered safe by regulatory standards, it remains an interim measure pending the development of more permanent disposal solutions.

20 years’ worth of spent nuclear fuel, safely stored at the former Maine Yankee nuclear plant. The energy produced from this fuel helped avoid 70 million metric tons of CO2 emissions. Source: https://www.energy.gov/ne/office-nuclear-energy

Recycling: Turning Waste into Worth

Recycling spent nuclear fuel is a contentious yet promising aspect of the fuel cycle. Countries like France have successfully implemented reprocessing plants, where spent fuel is chemically treated to extract 95% of the remaining uranium and plutonium. These materials can be reused in reactors, effectively maximizing the energy derived from each unit of uranium and reducing the volume of high-level waste.

However, the United States has largely eschewed recycling due to concerns over nuclear proliferation and the high costs associated with reprocessing technology. This decision highlights the delicate balance between economic incentives and security considerations in managing nuclear waste.

Waste Disposal: The Final Frontier

The ultimate goal of the nuclear fuel cycle is the safe, permanent disposal of high-level radioactive waste. Geological repositories, deep underground facilities designed to isolate waste from the biosphere for thousands of years, are the envisioned solution. However, political and public opposition has stalled the development of such repositories in many countries, leaving spent fuel in long-term storage facilities.

Developing a permanent disposal solution is a complex challenge, requiring not only technological advancements but also societal consensus.

Conclusion: The Orchestrated Symphony of Nuclear Energy

The nuclear fuel cycle is a testament to human ingenuity and the intricate balance of science, technology, and economics. From the depths of uranium mines to the heights of reactor cores, each stage plays a crucial role in transforming raw materials into the electricity that powers our world. Understanding this cycle reveals not only the mechanics of nuclear energy but also the profound economic and environmental implications it holds.

In the spirit of Nuclear Update, uncovering the hidden incentives and economic forces within the nuclear fuel cycle offers a deeper appreciation of its role in our energy landscape. It’s a complex, yet fascinating journey that underscores the potential of nuclear power to contribute to a sustainable and resilient energy future.

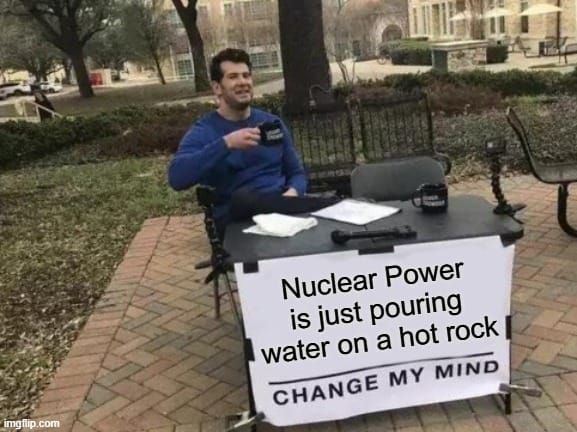

😂Meme of the Week

If you enjoyed this special holiday edition and would love to see more content like this from time to time, please let me know by rating and commenting below!

Wishing you a Happy New Year, may 2025 fuel even more nuclear breakthroughs.

See you next cycle!

Fredrik

💪Review of the Week

What did you think of this week's email? |

DISCLAIMER: None of this is financial advice. This newsletter is strictly educational and is not investment advice or a solicitation to buy or sell any assets or to make any financial decisions. Please be careful and do your own research

Reply